Why Plastic Heat Exchangers

High heat transfer, superior impact resistance, reduced fouling, and light weight......all in an equivalent package compared to traditional metal designs.

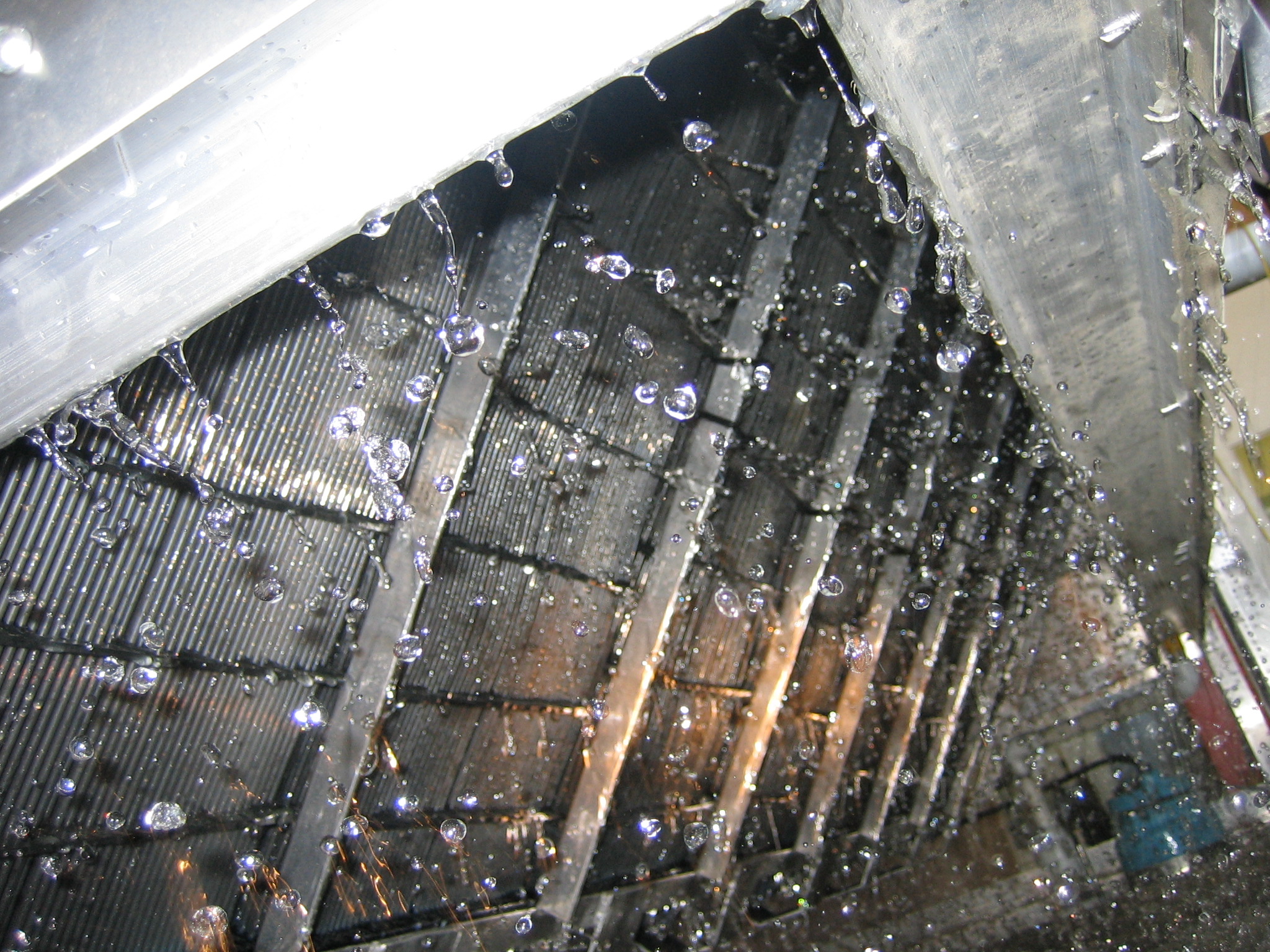

Corrosion Resistance

Our Polymer materials resist fouling and scale build-up. They do not corrode or degrade performance over time. They offer superior performance in salt water and highly corrosive applications.

Superior Impact Resistance

PolyCoil heat exchangers exhibit excellent impact resistance. There are no thin fins to bend and impede performance.

Light Weight

PolyCoil heat exchangers are typically much lighter than their metal counterparts. This makes for easier installation and less stress on supporting structures.

Fluid Compatibility

PolyCoil heat exchangers are compatible with a wide variety of fluids. If the fluid is compatible with the polymer used to make the exchanger (typically Nylon or HDPE) it will work with our Polycoils. Typical fluids include water, glycols, brine, chlorides, oils, etc.